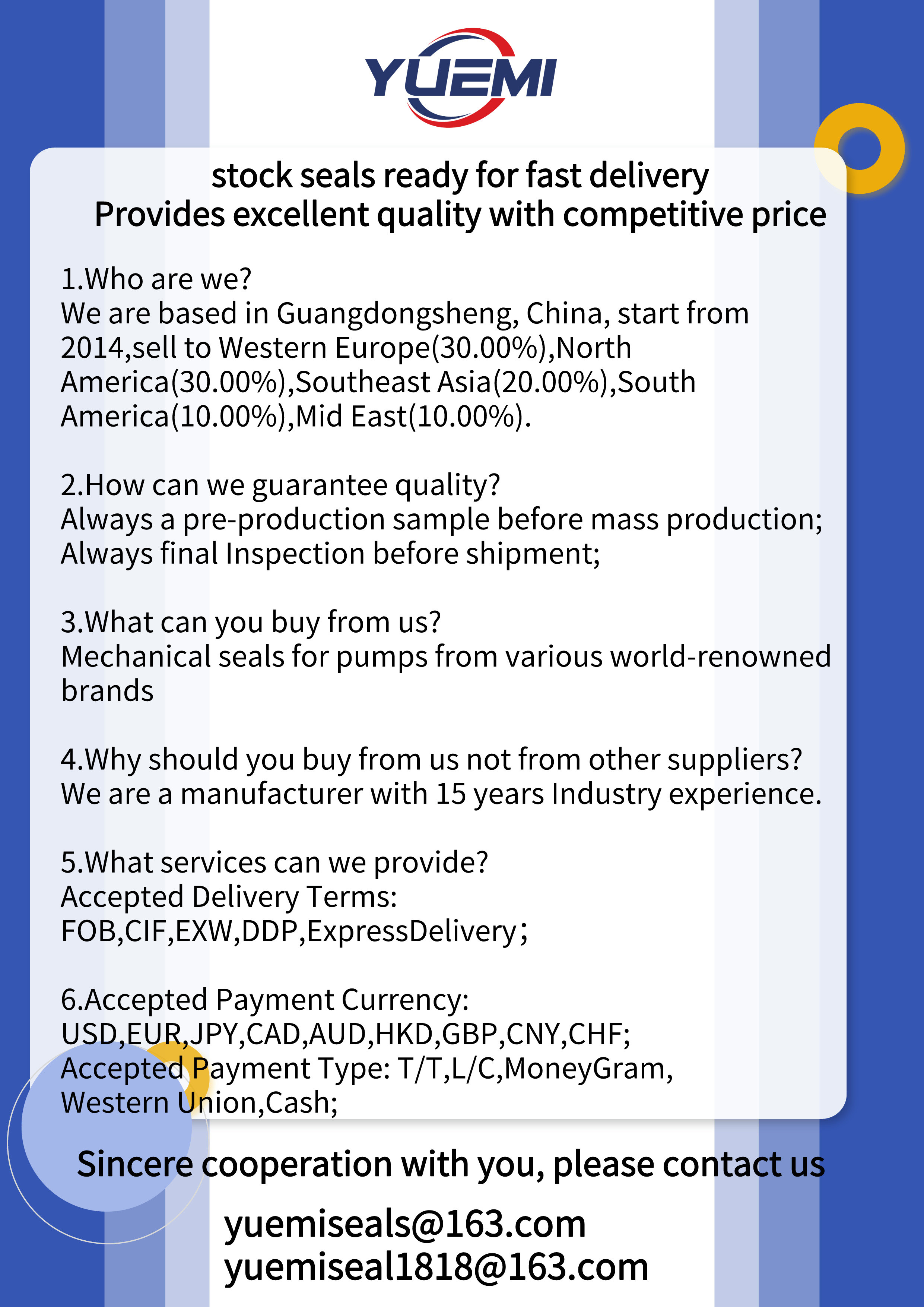

Guangzhou Yuemi Mechanical Seals Co., Ltd

Guangzhou Yuemi Mechanical Seals Co., Ltd. is a professional

enterprise engaged in the design, development, manufacturing, and

sales of various mechanical seals. We have complete production and

testing equipment, and a high-quality workforce. It has formed a

production capacity for various types of mechanical seals and is

one of the domestic production bases for mechanical seals.

We mainly produce various rubber products such as corrugated pipes,

rubber corrugated pipes, and O-ring gift rings. Mechanical seals

and assembly kits for carbon friction materials such as silicon

carbide, hard alloy, aluminum oxide ceramics, graphite, etc. The

products comply with DIN24960 and IS03

We produce various types of mechanical spring seals, including

single spring mechanical seals and multi spring mechanical seals.

Our main products include Groundfos Feili pump seals, O-ring seals,

ceramic seals, mechanical pump seals, non spring seals,

containerized seals, stainless steel seals, and elastomeric seals

Our product can completely replace Johnlane, Burgmann, AES Vulcan,

Roten

The series of product specifications are complete, including not

only major mechanical seal series models at home and abroad, but

also have certain surveying and prototype development capabilities,

which can solve the problem of importing foreign equipment and non

mechanical seals for users. The slogan of factory operation is:

"Business operators prioritize trust, customers first, and the

enterprise is willing to treat each other with sincerity, and

develop together with customers and mutual benefit with the spirit

of integrity."

The company's products can replace similar products such as

Burgman, John Crane, AES, Chesterton, Flowserve, Roter, etc. Widely

used in industries such as sewage treatment, agricultural

irrigation, petroleum, chemical, electric power, metallurgy,

pharmaceuticals, and food.

The company's products are highly praised by domestic and foreign

customers for their exquisite craftsmanship, excellent quality, and

durability. Welcome domestic and foreign new and old customers to

call, write, visit the factory for inspection, and negotiate!